3 Piece Aluminum Tin Can

Durable | Customizable | Food-Grade Certified

/3 Piece Aluminum Tin Can Product Overview/

Our 3 Piece Aluminum Tin Cans are engineered for premium packaging performance, combining a durable aluminum body with precise seam technology. Designed for both food and non-food applications, these cans offer excellent barrier properties against light, air, and moisture—preserving product freshness and quality over extended shelf life.

Made from high-grade, recyclable aluminum, they meet FDA and SGC standards, ensuring safety and sustainability in every production batch.

Key Features:

1.Material: 100% recyclable aluminum, food-grade coating

2.Structure: Body + Bottom + Lid (Three-piece construction)

3.Capacity Range: 100ml – 1,000ml (custom sizes available)

4.Printing: Up to 7 colors, 360° custom branding

Barrier Performance: Airtight sealing, anti-leak, moisture-proof

5.Certifications: FDA, SGS

/Why Choose Us?/

✅19+ Years Manufacturing Experience in aluminum packaging

✅Trusted by Global Brands in 75+ countries

✅Full Customization in size, shape, color, and branding

✅Strict Quality Control with batch testing and traceability

✅Sustainable Practices in compliance with environmental regulations

![beverage tin can Parmalat beverage tin can Parmalat]()

/3 Piece Aluminum Tin Can Applications/

Our 3-piece aluminum tin cans are widely used in beverage, food, chemical, and specialty goods industries. Their versatility and high sealing performance make them the go-to choice for brands seeking reliable packaging solutions.

Common Uses:

Food Industry: Powdered milk, coffee, tea, dried fruits, nuts, spices

Beverage Industry: Specialty drinks, energy powders, cocktail mixes

Promotional Packaging: Limited-edition products, gift sets, collector’s items

![Shandong-Jinzhou-tin can Shandong-Jinzhou-tin can]()

![Shandong-Jinzhou-tin can2 Shandong-Jinzhou-tin can2]()

![JZ aluminum tin can 1 JZ aluminum tin can 1]()

/ Aluminum Tin Can Production process/

We follow a strict, quality-controlled manufacturing process to ensure every can meets global packaging standards.

Step 1 – Material Selection

We source high-purity aluminum sheets, ensuring strength, corrosion resistance, and eco-friendliness.

Step 2 – Body Forming

Aluminum sheets are rolled and welded into cylindrical bodies, with smooth seams to prevent leakage.

Step 3 – Bottom Seaming

The can body is mechanically seamed with the bottom panel using precision equipment for airtight sealing.

Step 4 – Interior Coating

Food-grade epoxy or BPA-free coatings are applied inside to prevent interaction between contents and metal.

Step 5 – Printing & Decoration

High-definition offset printing (up to 7 colors) is applied for full branding coverage.

Step 6 – Lid Assembly & Packaging

Lids are either supplied separately or attached, with final inspection and secure packaging before shipment.

![tin can process tin can process]()

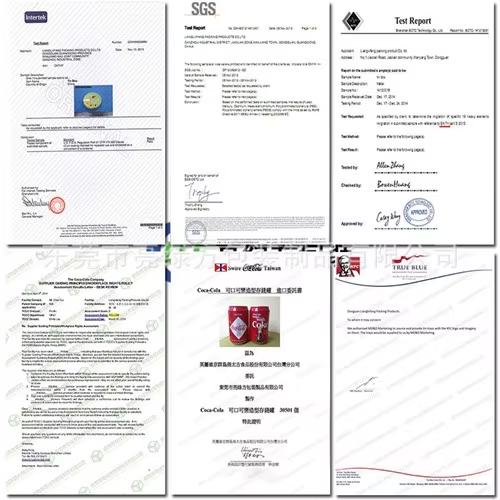

/Aluminum Tin Can certificate/

![JZ tin can certification JZ tin can certification]()

![JZ exhibition JZ exhibition]()

/Aluminum Tin Can Packaging&Delivery/

Packaging Information: For aluminum beverage cans, products are packed on pallets. Both standard packaging and customized packaging options are available.

Delivery Timeline: For aluminum beverage cans, shipment shall be effected within 21 working days upon receipt of payment.

![tin can delivery tin can delivery]()

/Our Factory/

Shandong Jinzhou Health Industry Co., Ltd. is based in Jinan, Shandong Province, and owns a 60,000-square-meter brewery. With over 19 years of experience in exporting through can channels—particularly specializing in canned beverages—it has built strategic collaborations with renowned suppliers in the industry. Jinzhou takes service as its core foundation and sticks to the commitment of addressing customers' needs. It is a company capable of providing one-stop solutions for beer and beverage production lines as well as packaging.

![aluminum tin can factory aluminum tin can factory]()

Looking for custom 3 Piece Aluminum Tin Cans for your brand?

Contact our expert team for packaging solution consultation.