|

Material

|

Aluminum Alloy 3004 (for body) and 5182 (for lid)

|

|

Capacity

|

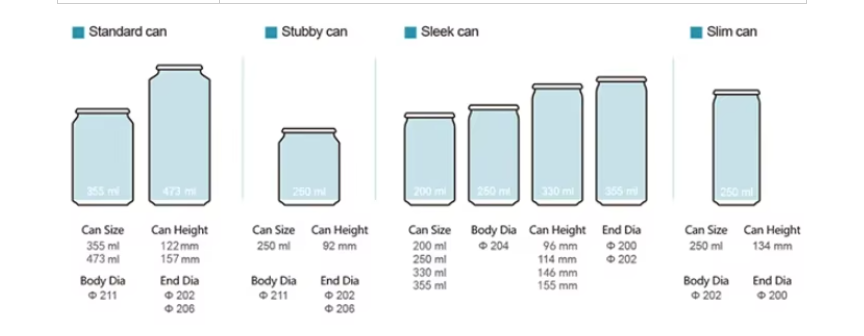

200ml, 250ml, 270ml, 330ml, 355ml, 450ml, 473ml, 500ml, 1L

|

|

Usage

|

Beer, Coffee, Juice, Soft Drinks, Soda, Sparkling Water, Energy Drink etc.

|

|

Printing Effect

|

Glossy, Matte, Tactile, Fluorescent etc.

|

|

Colors printed

|

Plain or customized printing(max 7 colors)

|

|

MOQ

|

plain:100000 printed :200,000

|

Aluminum can Material and process advantages

Lightweight and durable

We use 5052/5182 aluminum alloy, which is both lightweight and high strength, easy to carry and excellent compression performance .

The aluminum tank can effectively isolate oxygen, resist corrosion, light and moisture, maintain the taste and quality of the beverage, and extend the shelf life

Our Advantages

Personalized Aluminum Can Packaging Solutions

We offer fully customizable aluminum cans, including printing patterns, color matching, and brand identity design to enhance product recognition and boost market appeal.

Tailored Aluminum Can Structure

Adjustments such as pull ring design and inner coating processes are made based on your product’s unique characteristics to improve freshness retention and anti-counterfeiting performance. Plus, our aluminum cans are 100% recyclable, supporting sustainable, eco-friendly packaging.

Comprehensive Packaging Trends Support

We provide end-to-end packaging solutions—from material selection to final aluminum can packaging—helping beverage companies stay ahead in a competitive market.

Advanced Aluminum Can Production Capacity

Operating across 12 factories, we run state-of-the-art production lines with an annual output capacity of 10 billion aluminum cans, covering a full range of can sizes.

Customized Aluminum Can Decoration Services

Our expert printing and coating capabilities enable highly personalized aluminum can decoration to meet diverse customer demands.

19 Years of Aluminum Can Industry Experience

With nearly two decades of expertise in manufacturing 2-piece aluminum cans, we have exported products to over 75 countries and regions worldwide.

![1723798788070 1723798788070]()

![2 2]()

![1723799661176 1723799661176]()

FAQ About Aluminum Can

1. What are the main benefits of using aluminum cans for beverage packaging?

Aluminum cans offer excellent durability, lightweight design, and superior protection against light and oxygen, which helps preserve the flavor and freshness of beverages. Additionally, they are 100% recyclable, making them an eco-friendly packaging choice.

2. Can aluminum cans be fully customized for branding purposes?

Yes, aluminum cans support extensive customization options including printing, color matching, logos, and special finishes such as matte or glossy coatings. This allows brands to create unique and eye-catching packaging that stands out on store shelves.

3. Are aluminum cans safe for packaging all types of beverages?

Absolutely. Aluminum cans are coated with food-grade liners that prevent direct contact between the beverage and the metal, ensuring safety and preserving the taste and quality of products ranging from soft drinks to energy drinks and alcoholic beverages.

4. How does aluminum can recycling impact the environment?

Recycling aluminum cans significantly reduces energy consumption and carbon emissions compared to producing new aluminum. The recycling process is highly efficient, and cans can be recycled repeatedly without losing quality, supporting a circular economy.

5. What factors should be considered when choosing the right aluminum can size for my product?

Selecting the proper aluminum can size depends on your target market, product type, and consumption occasions. Factors like portability, serving size preferences, and shelf space should guide the decision to optimize both consumer appeal and production efficiency.

Professional factory customization, welcome to contact us for consultation

![1735625298541 1735625298541]()