[Jinzhou Packaging · Aluminum Can Life Cycle Series] Article 4

Presented by Jinzhou Packaging – Your Custom Aluminum Can Partner. Trusted by 300+ global brands, featuring high-speed production, food-grade OEM/ODM, and exporting to Southeast Asia, the Middle East, and Europe.

Introduction: That First Sip—It Determines Everything

For any beverage brand, flavor stability isn't just a marketing slogan; it’s a non-negotiable promise. The quality of that first sip is determined by whether the product suffers from:

Loss of carbonation

Flavor scalping or off-notes

Oxidation (stale flavors)

Premature shelf-life decay

And here’s the secret: 90% of these issues are decided at the exact moment of filling and sealing.

So, how exactly does an aluminum can manage to lock down gas, flavor, and freshness with such absolute certainty? Let's dive into the engineering.

I. Why Aluminum Cans are Naturally Superior for Gas Retention

When it comes to protecting what’s inside, the aluminum can has a massive, inherent advantage over other materials like PET bottles or composite cartons.

1. The Aluminum Can is a "Zero-Permeation" Fortress

Unlike plastics, which are microscopically porous, aluminum is a rigid, non-permeable packaging material.

Zero Oxygen Ingress: It blocks atmospheric oxygen from entering.

Zero CO₂ Loss: It prevents vital carbon dioxide (the fizz) from escaping.

Thermal Stability: Its structure is unaffected by typical environmental temperature fluctuations.

The takeaway: Provided the final seal is perfect, the can itself will virtually never suffer from "slow leakage." This is precisely why aluminum is the undisputed primary choice for highly carbonated drinks like beer, sparkling water, and energy drinks.

2. The Inner Coating: An Invisible Flavor Shield

To ensure the liquid never touches the metal, modern cans feature an internal lining—the true unsung hero of flavor preservation:

Food-Grade Coating: A thin layer of epoxy or BPA-NI (BPA Non-Intent) lacquer is sprayed onto the internal walls.

Complete Coverage: Although extremely thin, this coating must offer 100% complete coverage.

The role of this invisible barrier is singular: to completely isolate the liquid from the aluminum substrate. It prevents corrosion, stops any metallic taste from migrating into the drink, and ensures flavor stability over time.

![aluminum can filling aluminum can filling]()

II. The True Core: How We Prevent Oxidation During Filling

If flavor loss is the enemy, oxygen is the supervillain.

Even a residual presence of just 0.1% dissolved oxygen can lead to significant quality deterioration: beer turning stale, fruit juices darkening in color, and functional ingredients losing their potency.

1. The Critical Step: CO₂ / Nitrogen Pre-Purging

Before a single drop of product enters the can, a crucial gas displacement step takes place:

The empty can is flooded with inert gases, typically CO₂ or nitrogen.

This process effectively forces all atmospheric air out of the can, establishing a non-reactive (inert) environment.

This purging step sets the drink's very first line of defense against staling.

2. Isothermal Counter-Pressure Filling

Especially for carbonated beverages, the filling process is an act of delicate, high-speed balancing. This is known as Isothermal (Equal Pressure) Filling:

The pressure inside the can, the pressure of the filling head, and the speed of the liquid flow must be perfectly harmonized. This precision engineering ensures three vital outcomes:

![aluminum can with lid Double Seam aluminum can with lid Double Seam]()

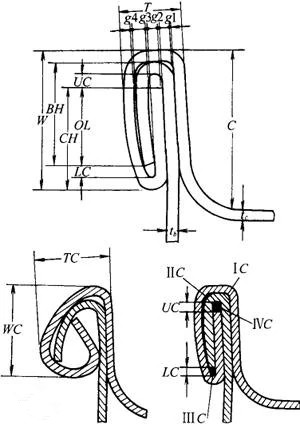

III. The Ultimate Defense: The Double Seam

If the steps above are about prevention, the final Double Seam process is the ultimate moment of truth—the definitive lock.

1. What is the "Double Seam"?

The can is not simply "lidded." The sealing process involves two powerful mechanical operations:

First Operation: The can body hook and the lid hook are interlocked (the structural bite).

Second Operation: This interlocking structure is powerfully pressed, flattening, and compressing the metal layers together.

The result is a metallic interlock structure—widely regarded as the most reliable method for sealing liquid packaging globally.

2. Why Aluminum Cans are Virtually Leak-Proof

The success of the double seam relies on its pure mechanical strength:

It is a metal-to-metal seal.

It has no glues that can degrade or age.

It is impervious to thermal expansion/contraction that plagues plastic caps.

When executed with qualified parameters, the double seam's integrity means the theoretical gas retention period can last for years.

IV. The Engineering View: Why Cans Have a Longer Shelf Life

From an engineering perspective, the aluminum can holds a triple advantage over almost every other packaging format:

| Parameter | Aluminum Can Performance |

| Oxygen Barrier | 100% |

| Light Barrier | 100% (Prevents photochemical reactions) |

| Gas Retention (CO₂) | Extremely High |

This is why we see a strong industry shift—from craft beers and sparkling waters to high-end functional beverages—moving from bottles to cans. The can simply provides a far more stable environment for delicate formulas.

V. Where 90% of Clients Make Mistakes (The Pitfalls)

As engineers in this industry, we’ve seen the most common failures, and surprisingly, the can itself is rarely the problem. The failure almost always lies in the system integration:

❌ Mismatch between Filler and Can Type: Using equipment calibrated for one can size on a different type.

❌ Seamer Parameter Neglect: Failing to precisely adjust the sealing parameters for a new lid specification.

❌ Inaccurate Necking: Poor precision on the can neck prevents a uniform seal.

❌ Skipping Seam Inspection: Ignoring the necessary destructive testing (Cut & Tear Down analysis) to verify the seam integrity.

The true challenge is the harmonious coordination between the Can + Lid + Filling System.

Conclusion: Flavor Isn't Protected; It’s Engineered

The stable flavor profile that consumers enjoy in every sip is the result of a precise blend of engineering principles: Gas Control, Filling Process Excellence, and Absolute Sealing Structure.

The aluminum can isn't just a simple container; it is an indispensable component of Flavor Engineering.

Jinzhou Packaging: Your Expert Partner in Can Structure and Filling Line Adaptation

At Jinzhou Packaging, we provide more than just quality aluminum cans; we offer the expertise to ensure optimal performance on your line:

Can Body & Filling Line Matching

Can End & Seam Stability Guidance

High Gas Retention & Seal Design

Export-Grade Quality Control

Whether your product is Beer, Sparkling Water, Functional Drinks, or CSDs, we help you lock your flavor into the perfect aluminum package.

Start Your Custom Aluminum Can Project Today

Official Website: https://www.jinzhouhi.com/cans.html

Contact: Jinzhou Packaging |admin@jinzhouhi.com