Have you ever wondered why aluminum beverage cans are so popular? In recent years, beverage brands have increasingly turned to aluminum packaging. This shift is driven by the need for sustainability and convenience in consumer choices.

In this post, we’ll explore how recyclability and convenience are key reasons for this trend.

Understanding Aluminum Beverage Cans

What Are Aluminum Beverage Cans?

Aluminum beverage cans are lightweight containers made primarily from aluminum. They are designed to hold a variety of drinks, providing an effective barrier against light and oxygen. This helps preserve the flavor and freshness of the contents.

Common types of beverages packaged in aluminum cans include:

● Carbonated Drinks: Sodas and sparkling waters are often found in these cans.

● Coffee Drinks: Ready-to-drink coffee beverages are gaining popularity.

● Functional Drinks: These include energy drinks and sports drinks.

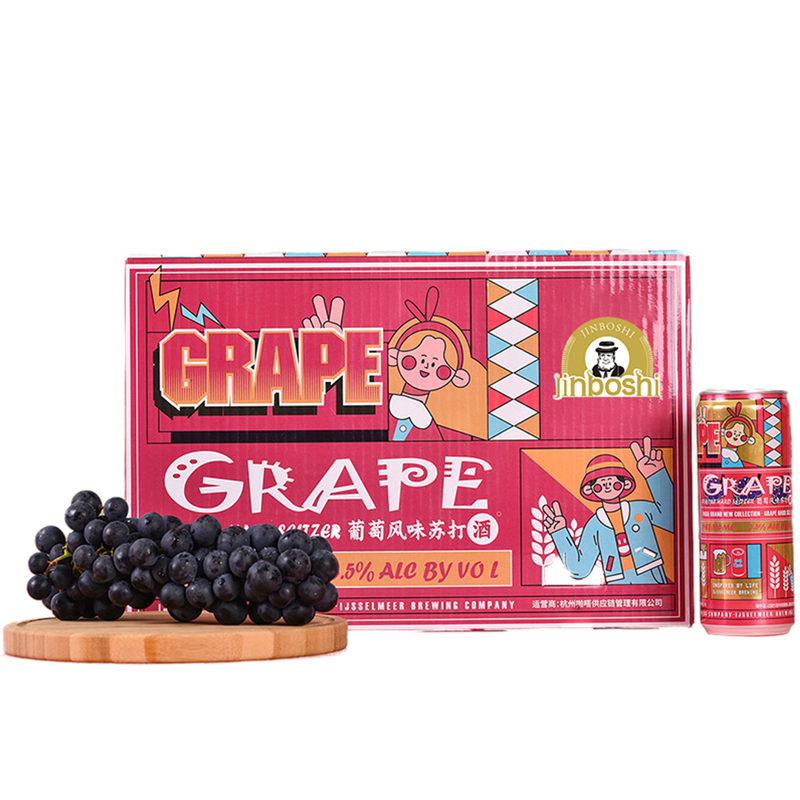

● Alcohol-Infused Beverages: Many craft beers and hard seltzers use aluminum cans.

● Fruit-Flavored Drinks: Juices and flavored waters are also packaged in aluminum.

The Manufacturing Process of Aluminum Cans

The production of aluminum cans involves several key steps. First, raw aluminum is extracted and processed into sheets. These sheets are then formed into can bodies through a process called “drawing and ironing.”

Here's a simplified overview of the manufacturing process:

1. Aluminum Sheet Production: Aluminum is mined and refined into sheets.

2. Can Forming: The sheets are cut and shaped into can bodies.

3. Printing and Coating: Cans are printed with labels and coated for protection.

4. Filling: Beverages are filled into the cans and sealed.

Environmental Considerations

The manufacturing process has improved significantly over the decades. Here are some environmental highlights:

● Resource Efficiency: Modern techniques use less energy and water.

● Reduced Waste: The industry has minimized waste through recycling and reusing materials.

● Lower Emissions: Advances have led to a decrease in greenhouse gas emissions during production.

These improvements not only make aluminum cans more sustainable but also enhance their appeal to environmentally conscious consumers.

![330ml Pre-Mixed Hard Seltzer vodka flavored Cocktail Drink 330ml Pre-Mixed Hard Seltzer vodka flavored Cocktail Drink]()

The Recyclability of Aluminum Beverage Cans

Why Recyclability Matters

Packaging waste is a significant environmental issue. Every year, millions of tons of waste end up in landfills, harming ecosystems. This is where recyclability plays a crucial role.

Brands are increasingly focused on sustainability, responding to consumer demand for eco-friendly products. Eco-conscious consumers prefer brands that prioritize recycling and sustainable practices. By choosing aluminum cans, companies demonstrate a commitment to reducing their environmental footprint.

Aluminum's Unique Recycling Properties

Aluminum is a standout material in the recycling world. It can be recycled infinitely without losing quality. This means that every aluminum can can be turned into a new can over and over again.

Let’s compare aluminum to other common packaging materials:

Material | Recycling Rate | Environmental Impact |

Aluminum | 71% | Low emissions, infinite recyclability |

Plastic | 9% | High pollution, often down-cycled |

Glass | 30% | Heavy, high energy use in recycling |

As you can see, aluminum outperforms plastic and glass in both recycling rates and overall environmental impact.

The Recycling Process of Aluminum Cans

Recycling aluminum cans involves several straightforward steps:

1. Collection: Used cans are collected from recycling bins and centers.

2. Sorting: Cans are sorted from other materials, ensuring purity.

3. Cleaning: They are washed to remove any residue.

4. Shredding: Clean cans are shredded into small pieces.

5. Melting: Shredded aluminum is melted down at high temperatures.

6. Reforming: The molten aluminum is then formed into new sheets for can production.

This process is part of a closed-loop recycling system. This means the recycled material is used to create new products, like aluminum cans, without degradation. Unlike many materials, aluminum cans do not get down-cycled, ensuring they maintain their value and utility.

Industry Statistics on Recycling

The statistics surrounding aluminum can recycling are impressive. Currently, 71% of aluminum cans are recycled. This high rate contributes significantly to resource conservation.

Additionally, recycling aluminum cans has led to a 43% reduction in greenhouse gas emissions since 1991. This demonstrates the positive impact recycling has on the environment, making aluminum cans a smart choice for both brands and consumers.

Convenience of Aluminum Beverage Cans

Lightweight and Portable Design

Aluminum beverage cans are incredibly lightweight. This makes them easy to carry, which is a big plus for consumers. Whether you’re heading to a picnic, a party, or just running errands, aluminum cans fit perfectly in bags or coolers.

● On-the-Go Consumption: Their portability allows for convenient enjoyment anywhere.

● Easy to Store: They take up less space, making them ideal for travel.

This lightweight nature enhances the overall consumer experience, allowing people to enjoy their favorite drinks without the hassle of heavy containers.

Storage and Transportation Efficiency

One of the standout features of aluminum cans is their stackable design. This is beneficial for brands and retailers alike. Here’s how:

● Stackability: Cans can be neatly stacked, maximizing storage space.

● Cost Savings: Because they are lightweight, brands can ship more beverages using less material.

For example, a truckload of aluminum cans can carry significantly more product than glass bottles, leading to lower transportation costs. This efficiency benefits both companies and consumers.

Quick Cooling and Freshness Preservation

Aluminum cans chill faster than glass or plastic containers. This is crucial for consumers who want their drinks cold and refreshing. Here’s why aluminum is superior:

● Faster Cooling: The thin walls of aluminum allow beverages to cool quickly in a fridge or cooler.

● Airtight Seal: Aluminum cans provide an airtight seal, protecting the flavor and freshness of drinks. This is especially important for products like coffee drinks and carbonated beverages.

In summary, the convenience of aluminum beverage cans enhances the drinking experience, making them a preferred choice for many consumers.

Market Trends Influencing Aluminum Packaging Choices

Consumer Preferences for Sustainable Packaging

Today’s consumers are increasingly leaning towards sustainable packaging options. They are more aware of environmental issues and prefer brands that align with their values. Here are some insights into this behavior:

● Eco-Conscious Choices: Many shoppers actively seek products in recyclable packaging, like aluminum cans.

● Brand Loyalty: Companies using sustainable materials often gain more loyal customers.

Brands like Coca-Cola and Heineken have successfully leveraged aluminum packaging in their marketing strategies. They highlight the sustainability of their cans, which resonates well with health-oriented formulations. This not only attracts eco-conscious consumers but also enhances brand image.

The Rise of Health-Conscious Products

The beverage industry is seeing a notable shift towards health-oriented products. Consumers are now more focused on what they drink, leading to an increase in sugar-free and zero-calorie options.

● Functional Drinks: Many brands are introducing functional beverages, such as electrolyte-infused waters and energy drinks.

● Aluminum's Role: Aluminum cans are ideal for these products. They keep drinks fresh and maintain their benefits.

For example, brands like LaCroix and Zevia package their health-focused beverages in aluminum cans, appealing to consumers who prioritize wellness. This trend shows how aluminum packaging supports the growing demand for healthier options while maintaining convenience.

In conclusion, the market trends clearly indicate that consumer preferences for sustainable and health-conscious products are driving beverage brands to opt for aluminum packaging.

Competitive Landscape: Brands Leading with Aluminum Packaging

Case Studies of Successful Brands

Several brands have effectively embraced aluminum beverage cans, showcasing innovative marketing strategies. Here are a few notable examples:

● Coca-Cola: This iconic brand has long utilized aluminum cans, promoting their recyclability in campaigns. Their “Share a Coke” campaign personalized cans, enhancing consumer engagement and brand loyalty.

● Heineken: Heineken’s commitment to sustainability is evident in its use of aluminum. They have launched limited-edition cans that emphasize eco-friendliness, appealing to environmentally conscious consumers.

These brands not only focus on product recognition but also foster strong connections with their audiences. By showcasing the benefits of aluminum packaging, they enhance brand loyalty and drive sales.

OEM/ODM Service Capabilities in the Aluminum Beverage Can Market

Manufacturers in the aluminum beverage can market are increasingly offering OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer) services. This customization is crucial for brands looking to stand out.

● Customization Options: Brands can tailor their cans, including unique designs, sizes, and even formulations. This flexibility allows for private label solutions, catering to specific market needs.

● Differentiation: In a crowded market, tailored products help brands differentiate themselves. Customization can include health-oriented formulations or seasonal flavors, appealing to niche markets.

By leveraging these services, beverage companies can create unique offerings that resonate with consumers, enhancing their competitive edge in the industry.

The competitive landscape is evolving, and brands that effectively utilize aluminum packaging are leading the way in innovation and consumer engagement.

![OEM 3-8% Alcohol Canned Hard Seltzer grapefruit flavor sparkling Mix Cocktails OEM 3-8% Alcohol Canned Hard Seltzer grapefruit flavor sparkling Mix Cocktails]()

Challenges and Considerations

Limitations of Aluminum Packaging

While aluminum beverage cans have many advantages, they also come with some limitations. Here are a few potential drawbacks:

● Consumer Perception: Some consumers still prefer glass or plastic, believing them to be safer or more premium. This perception can impact sales of aluminum-packaged products.

● Recycling Challenges: Although aluminum is recyclable, not all consumers recycle properly. Misplaced cans can end up in landfills, which undermines sustainability efforts.

Additionally, misconceptions about aluminum, such as concerns over leaching or taste, can affect consumer choices. Brands need to address these issues through education and transparent communication.

Future of Aluminum Packaging in the Beverage Industry

The future of aluminum packaging looks promising, driven by several emerging trends. Here’s what to watch for:

● Innovations in Packaging Technology: New developments are enhancing the functionality of aluminum cans. For instance, some manufacturers are exploring lightweight designs that maintain strength while reducing material use.

● Sustainability Focus: As consumers become more environmentally conscious, the demand for sustainable packaging will grow. Brands will likely prioritize aluminum due to its recyclability.

Predictions suggest that consumer preferences will continue to evolve. We might see a shift toward more eco-friendly options, with aluminum cans leading the way in convenience and sustainability.

In summary, while challenges exist, the potential for aluminum packaging in the beverage industry remains strong.

Conclusion

This article highlights the key reasons beverage brands choose aluminum packaging.

Recyclability and convenience are crucial factors driving this trend.

Aluminum cans not only appeal to eco-conscious consumers but also enhance brand loyalty.

Brands should consider incorporating aluminum cans into their packaging strategies to meet evolving consumer demands.

FAQ

Q: Are aluminum beverage cans recyclable?

A: Yes, aluminum beverage cans are highly recyclable, and recycling them saves energy and resources.

Q: How do aluminum cans compare to plastic in terms of environmental impact?

A: Aluminum cans have a lower carbon footprint than plastic, as they are more easily recycled and reused.

Q: What types of beverages are commonly packaged in aluminum cans?

A: Common beverages include soft drinks, beer, energy drinks, and flavored waters.

Q: How can consumers ensure they are recycling aluminum cans correctly?

A: Consumers should rinse cans, remove labels if possible, and place them in designated recycling bins.