Did you know that beer cans revolutionized the beverage industry? These simple containers have a rich history and play a crucial role today. In this article, we’ll explore the evolution of beer cans and their ongoing significance. You’ll discover why beer cans remain a popular choice for consumers and manufacturers alike.

Introduction

Beer cans have transformed the beverage industry significantly. They are not just containers; they represent a shift in how we consume beer.

Significance of Beer Cans:

● Convenience: Lightweight and portable, they’re perfect for any occasion.

● Safety: Unlike glass, they don’t shatter, making them safer for outdoor events.

Understanding the history and evolution of beer cans is essential. It reveals how innovations have shaped consumer preferences and industry standards.

Key Points:

● Beer cans began as a practical solution to packaging.

● Their design has evolved over the years, enhancing usability and appeal.

The term "Beer Cans" encompasses various styles and sizes, reflecting the diversity in the market today. As we explore this topic, we’ll uncover the fascinating journey of beer cans and their ongoing relevance.

The Evolution of Beer Cans

Early Beginnings

Beer cans first appeared in the early 1930s. The United States saw the introduction of these innovative containers. Initially, they were made from steel, which was heavy and less convenient.

As demand grew, manufacturers began exploring lighter materials. Aluminum emerged as a popular alternative due to its weight and resistance to corrosion.

The initial purpose of beer cans was simple: to provide a portable and durable option for consumers. However, their acceptance was gradual. Many people preferred glass bottles at first. Over time, the convenience of cans won over consumers, leading to their widespread use.

Technological Advancements

Throughout the decades, beer can design has undergone significant changes. One major innovation was the introduction of the "stay-on-tab" in the 1970s. This feature made it easier for consumers to open cans without needing a separate tool.

The shift from steel to aluminum brought several benefits. Aluminum cans are lighter, which reduces shipping costs. They also cool down faster, enhancing the drinking experience.

Another advancement was the development of thinner can walls. This innovation improved material efficiency, allowing manufacturers to use less aluminum while maintaining strength.

Key Innovations:

● Stay-on-tab design (1970s)

● Shift from steel to aluminum

● Thinner can walls for efficiency

Modern Manufacturing Techniques

Today, beer cans are produced using advanced manufacturing techniques. Most cans are made from aluminum, which is not only lightweight but also highly recyclable.

Modern processes ensure consistency and quality in production. This efficiency translates to cost savings for manufacturers.

The impact of lightweight materials is significant. Shipping and storage costs are reduced, benefiting both producers and retailers.

Cost-Effectiveness of Aluminum Cans:

● Lower shipping costs due to reduced weight

● Easier handling and storage

● Higher recycling rates compared to glass

Overall, the evolution of beer cans reflects ongoing innovation. From their early beginnings to modern production, they remain a vital part of the beverage industry.

Specifications and Varieties of Beer Cans

Common Sizes and Capacities

Beer cans come in various sizes, catering to different preferences and occasions. The most common sizes include:

● 330ml: A standard size for many light beers.

● 500ml: Popular among craft breweries and larger servings.

In addition to these, there are expanded options like:

● 800ml: Great for sharing or enjoying a longer session.

● 1000ml: Often seen in specialty or limited-edition releases.

● 1L cans: Perfect for gatherings and parties.

These variations allow consumers to choose the perfect amount for their needs.

Alcohol Content Variations

When it comes to beer, alcohol content matters. This is measured by ABV (alcohol by volume). It indicates the percentage of alcohol in a beverage.

Beer cans typically range in ABV from mild to strong options:

● Mild beers: Generally have an ABV of ≥3.3% vol. These are easy to drink and refreshing.

● Stronger beers: Can reach up to 5.6% vol or more. These often have bolder flavors and richer profiles.

Consumers can enjoy a wide variety of choices based on their taste preferences and desired effects.

Styles of Beer in Cans

Beer cans hold a diverse range of styles. Here are some traditional and specialty options:

● Traditional styles:

○ Lager: Crisp and refreshing, perfect for hot days.

○ Stout: Dark and rich, often with coffee or chocolate notes.

○ Pale Ale: Balanced with a hoppy flavor and moderate bitterness.

● Specialty styles:

○ Craft wheat beer: Light and often fruity, great for summer.

○ Flavored fruit beer: Infused with various fruits for a unique twist.

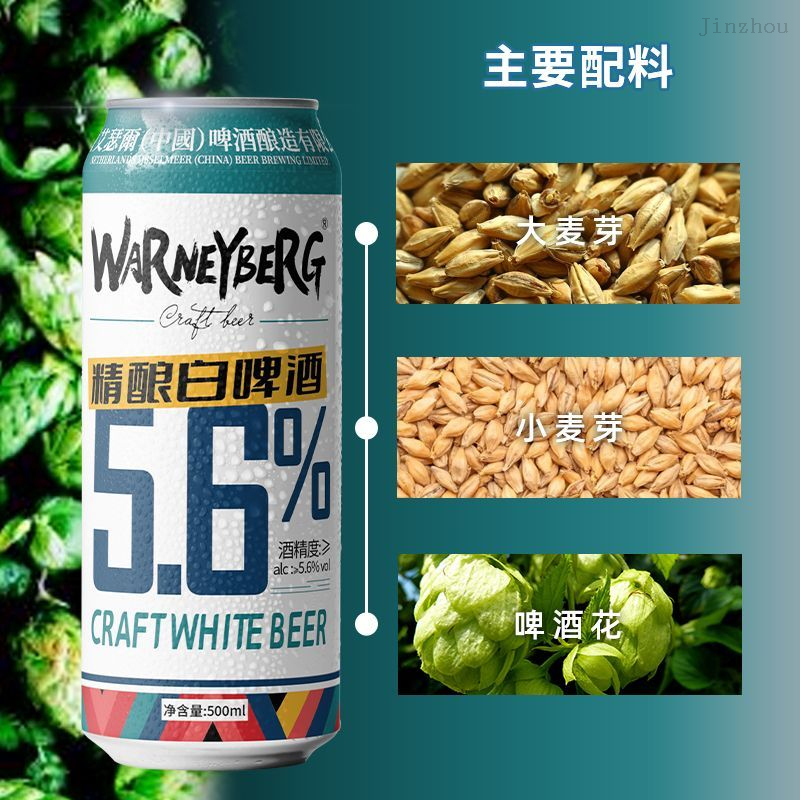

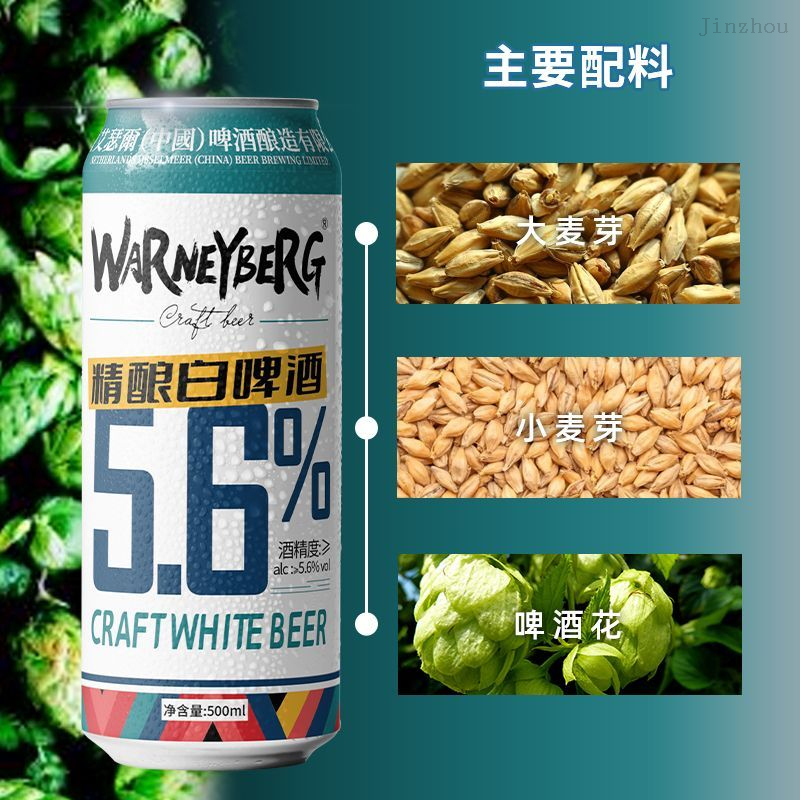

Foundational Ingredients: The ingredients used in beer production play a crucial role in flavor. Key ingredients include:

● Barley malt: Provides sweetness and body.

● Wheat malt: Adds smoothness and a light finish.

● Hops: Contributes bitterness and aroma.

These varieties and specifications showcase the versatility of beer cans, making them a popular choice among consumers.

Core Advantages of Beer Cans

Portability and Durability

When comparing beer cans to glass bottles, portability stands out. Cans are lighter, making them easier to carry. They’re less likely to break, which is a significant advantage during outdoor activities or travel.

Imagine heading to a picnic or camping trip. Beer cans are perfect for these scenarios. Their sturdy design means you don't have to worry about shattered glass.

Additionally, the pull-tab design makes opening a can simple and quick. No bottle opener is needed. Just pop it open and enjoy!

Light Protection and Shelf Life

One of the key benefits of beer cans is their ability to protect contents from UV rays. The opaque nature of cans keeps harmful light away from the beer. This is crucial for preserving flavor and quality.

Cans can significantly extend shelf life compared to glass bottles. While glass can allow light to seep in, leading to skunky flavors, cans maintain the integrity of the beer.

Shelf Life Comparison:

● Beer Cans: Longer shelf life, better flavor preservation.

● Glass Bottles: More susceptible to light exposure, shorter shelf life.

Eco-Friendliness and Recyclability

Beer cans are eco-friendly! Both aluminum and steel cans are highly recyclable. This means they can be processed and reused, reducing waste.

Recycling beer cans offers substantial energy savings. In fact, using recycled aluminum requires 95% less energy than producing new aluminum.

Environmental Benefits:

● Reduced landfill waste.

● Lower carbon footprint.

● Conservation of natural resources.

Customization and Branding Opportunities

Customization plays a vital role in the beer can industry. OEM services allow brands to create unique designs that stand out on shelves.

Through can design, brands can build distinct identities. This includes everything from label printing to color schemes.

Importance of Packaging Design:

● Attracts consumer attention.

● Communicates brand values.

● Enhances overall marketing strategy.

These core advantages highlight why beer cans remain a popular choice in the beverage industry. They offer practicality, sustainability, and branding potential that glass simply can't match.

Competitor Comparison: Beer Cans vs. Glass Bottles

Advantages of Beer Cans

Beer cans offer numerous advantages over glass bottles. Here are some key benefits:

● Lightweight: Cans are easier to carry, making them ideal for outdoor activities.

● Shatterproof: Unlike glass, cans don’t break easily, reducing safety concerns.

● Better UV Protection: Cans block harmful UV rays, preserving the beer’s flavor longer.

These features make beer cans a practical choice for many consumers.

Advantages of Glass Bottles

On the other hand, glass bottles have their own set of advantages. For instance:

● Slightly Better Airtightness: Glass can provide a more airtight seal, which may help maintain freshness.

● Visual Appeal: Many consumers find the look of glass bottles more attractive, especially for premium products.

However, it’s important to consider the energy consumption involved in recycling. Recycling glass typically requires more energy than recycling aluminum. This can impact the overall sustainability of using glass.

Energy Consumption Comparison:

● Glass: Higher energy costs for recycling.

● Aluminum: Requires significantly less energy, making it a greener option.

Market Trends

The market for beer packaging is evolving. Here’s a look at current trends:

● Premium Craft Beer Cans: More craft breweries are using cans to showcase their products. Cans allow for unique designs and branding opportunities.

● Casual Consumer Options: Many mainstream brands are also shifting to cans, appealing to a broader audience.

Sustainability is a major focus. Brands are increasingly using recycled materials in their packaging. This aligns with consumer preferences, which are shifting towards eco-friendly options.

Consumer Preferences:

● Growing demand for sustainable packaging.

● Increased interest in products made from recycled materials.

These trends indicate a significant shift in how consumers view beer packaging. As awareness of environmental issues rises, the popularity of beer cans continues to grow.

![Brewery Flavor Alcohol Craft Super Strong Dark Stout Beer in Cans Brewery Flavor Alcohol Craft Super Strong Dark Stout Beer in Cans]()

Modern Practicality of Beer Cans

Versatility in Distribution Channels

Beer cans excel in various distribution channels, particularly in non-on-premise sales. They’re commonly found in supermarkets and convenience stores, making them accessible to a wide range of consumers.

Benefits of Single-Serve Packaging:

● Waste Reduction: Single-serve cans help minimize waste, offering just the right amount for many drinkers.

● Space-Efficient Storage: Cans can be stacked easily, optimizing storage space both in stores and during transport.

This versatility makes beer cans a practical choice for retailers and consumers alike.

Cost Efficiency for Manufacturers

When it comes to cost efficiency, beer cans have significant advantages. Here’s how:

● Production Savings: Cans are cheaper to produce than glass bottles, allowing manufacturers to save on costs.

● Shipping Cost Savings: Their lightweight nature reduces shipping expenses, which can be substantial for large orders.

These savings can impact ingredient quality and consumer pricing positively. Additionally, cans have lower breakage rates compared to glass, further reducing costs associated with damaged products.

Cost Analysis:

● Cans: Lower production and shipping costs, reduced breakage.

● Glass: Higher costs due to fragility and heavier weight.

Alignment with Sustainability Goals

Beer cans are increasingly aligned with sustainability goals. They play a significant role in helping brands achieve carbon neutrality.

Consumer Preferences: There’s a noticeable shift towards sustainable packaging options. Many consumers prefer products that are environmentally friendly.

Recyclability Rates:

● High Recyclability: Over 95% of beer cans are recyclable in top markets.

● Environmental Impact: Using recycled materials significantly reduces the carbon footprint.

This alignment with sustainability not only meets consumer demands but also supports a healthier planet. Beer cans are truly a modern solution for today’s brewing industry.

Conclusion

Beer cans have a rich history and remain highly useful today. Their lightweight, shatterproof design and excellent UV protection make them a practical choice.

As sustainability becomes crucial, beer cans align well with eco-friendly practices. The future looks bright for beer cans in the beverage industry.

Consider the benefits of beer cans when making your choices. They offer convenience, cost savings, and environmental advantages.

FAQ

Q: What are the most common sizes of beer cans?

A: The most common sizes are 12 oz, 16 oz, and 19.2 oz.

Q: How are beer cans recycled?

A: Beer cans are recycled through a process involving shredding, melting, and reforming into new aluminum products.

Q: Why are beer cans considered better than glass bottles for some consumers?

A: Cans are lightweight, shatterproof, and provide better UV protection, making them more convenient and safer.

Q: What innovations can we expect in the future of beer can design?

A: Future designs may include enhanced sustainability features, improved sealing technology, and unique artwork for branding.

Q: What are the typical alcohol content levels found in beer cans?

A: Typical alcohol content levels range from 4% to 8%, depending on the beer style.